Suppliers & Makers

Here, Now

We go the extra mile to make everything in the British Isles.

We make here for a host of reasons; we can make in small quantities and we can avoid shipping charges, customs delays and exchange rate variables. We can make our mistakes small and we can repair them fast. We can meet our makers, learn from them and work closely with them to make sure we are making the best coats we can.

Beyond the practical considerations, there are human ones. Our hope is that in our small way, we can contribute to opportunities for our suppliers and makers. By helping to showcase their work, we hope to sustain and preserve the fantastic mills and skills and makers that we have here.

We know that we must if current livelihoods are to survive and future generations are able to train with and succeed them. The cost of us not working with them is bigger than we might imagine.

Musa Apparel

Our makers are Musa Apparel in East London. It is thanks to the skilled hands and practiced eyes of Musa's makers, their well-oiled machines and sharpened shears, that our designs are brought to life.

The construction of our coats is intricate and their making requires careful handling and meticulous attention to detail. We offer our styles in a broad size range in an unusually extensive array of fabrics – often in different widths and with many different patterns, weights and handles. To make each coat, the pattern lay-out must be reconsidered, the weighting altered; customisations and size alterations carried through.

Working with Musa enables us to make our coats exactly the way our customers want them, minimising wastage. It also allows us to offer repair and alteration services, giving fresh life to customers' coats when they need it. And last, but by no means least, it provides opportunities for skilled workers, here – preserving skills and sustaining livelihoods.

Our Textiles

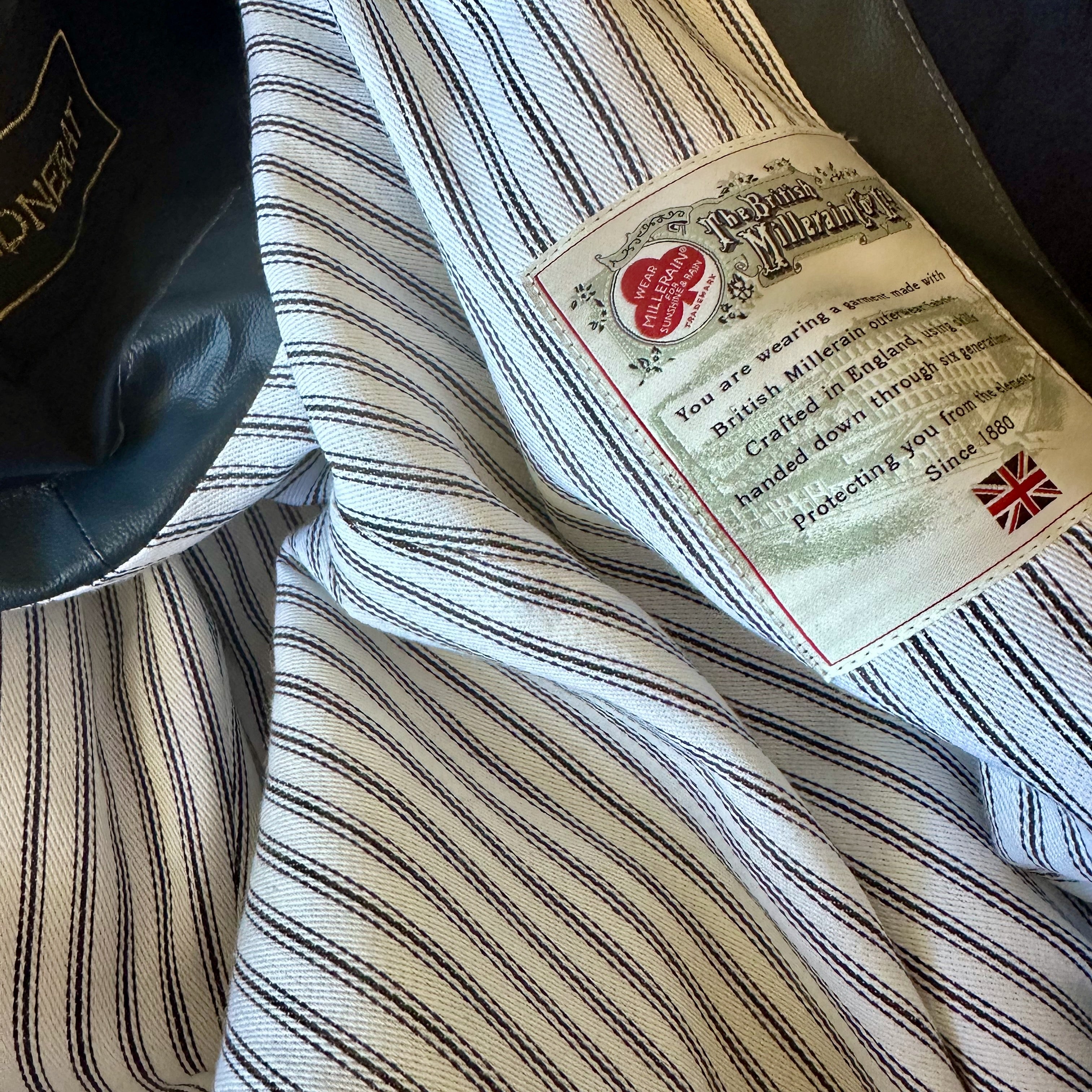

EdNerat sources all its fabrics with great care in the United Kingdom.

We are thrilled to have found and to be able to work with a wide and growing array of family-owned and centuries-old mills and weavers who work with true craftsmanship to produce their textiles.

All our wonderful wools, tactile tweeds, fantastic flannels, beautiful bouclés, luscious linens and bewitching brocades are made with exacting craftsmanship here in the United Kingdom.

Owing to the lack of British makers, we have made an exception to our "made in Britain" rule with our light silk linings and silk matkas.

Our Weavers

Amongst our marvellous suppliers are the likes of the legendary and utterly magical Linton Tweeds, original and first supplier of tweed to Chanel. AW Hainsworth, which has clothed royalty, dressed palaces and created ceremonial military cloths for more than two centuries, provides us with jewel-like solid-coloured merino wools – both warm and wearable!

The delightful Somerset-based Fox Brothers, original creators of flannel and purveyors to everyone on Saville Row, spoil us with the most luxuriously soft merino jacketing. And finally (for the moment) there is Stephen Walters, a Suffolk-based artisan weaver of three centuries standing. Makers of fabrics for coronation robes and state coaches, royal wedding dresses and more, for EdNerat they weave the most bewitching of brocades.

Sustainable Sourcing

We always buy in short lengths which has three key advantages.

Firstly, it means we can keep wastage low – we don't end up throwing away huge roll-ends.

Secondly, and rather excitingly, it means that we can spend heaps of time selecting from the rich and ever-changing array of fabulous fabrics that British mills produce.

Thirdly, it means you won't be one of hundreds wearing any one of our coats. Many of the fabrics we use are only produced in limited quantities and we buy short lengths of these. Most of our coats are produced from these short runs of fabric, a subset are true one-offs.

Zero Waste

We also occasionally source high quality British-made end of rolls and remnants, supporting these and other businesses while helping to reduce waste and keep costs down.

As all makers do, we end up with short ends and scraps. The longer pieces are used by Weskit, the smaller pieces are made into the most beautiful padded coat-hangers for us by Anne in Pencoed, the smaller bits into padded hairbands by Vanessa Rose in Somerset.

We ship and print on recycled and recyclable card, cardboard and paper. Where we can, we re-use things, where we can't we compost them. Any customers wanting to return their packaging to us is welcome to; we will pay for the postage and re-use their boxes for storage, their ribbons for tying up samples, swatches and patterns and their tissue for our boots and bags!

Packaging

We ship our coats carefully wrapped in re-cycled Kraft tissue paper. The tissue helps prevent the coats from creasing too much and is worth holding onto for travelling or to shape shoes, boots and handbags. Once wrapped in the tissue, our coats are packed in beautiful hand-crafted boxes covered in re-cycled Kraft paper. Our boxes are made for us by MacCarthy & Sons, a wonderful fifth-generation family business in Woolwich using traditional box-making techniques. We hope you will hold on to your box and find a good use for it; if you don’t have room for it, you can always compost it – but ideally, please let us know. We will cover the return postage and use your box for storage.

Every bit counts

Our leather bias is made in Somerset

Our buttons are covered in Kent

Our garment labels are embroidered in London

Our stationery is printed in London, Wales & Cornwall

Our quilting is sewn in Lancashire

Our care labels are woven in Wales

Our coat covers & carriers are made in the Midlands

Our quilting is sewn in Lancashire

Our sealing wax is made in Scotland

Our art work is designed in Essex